Partners

Fraunhofer ISC | GHENT UNIVERSITY | HUTCHINSON | impulstec | Bavarian Research Alliance | CEPA

Four partners and two associated partners are bringing their knowledge together in the RecyLib project to improve and validate the recycling and re-use of recycled functional materials: with new manufacturing processes, improved separation technologies and recycling-friendly design.

The Fraunhofer Institute for Silicate Research ISC is one of the leading german R&D centers for material-based research and development in the fields of energy, environment and health. Fraunhofer ISC co-ordinates the RecyLIB project and focuses within the project on cell manufacturing and electrochemical ageing as well as separation technology and regenerating materials for future resource efficient battery recycling technologies.

Dr. Michael Hofmann

(Project Co-Ordinator, Fraunhofer ISC)

E-Mail: michael.hofman@isc.fraunhofer.de

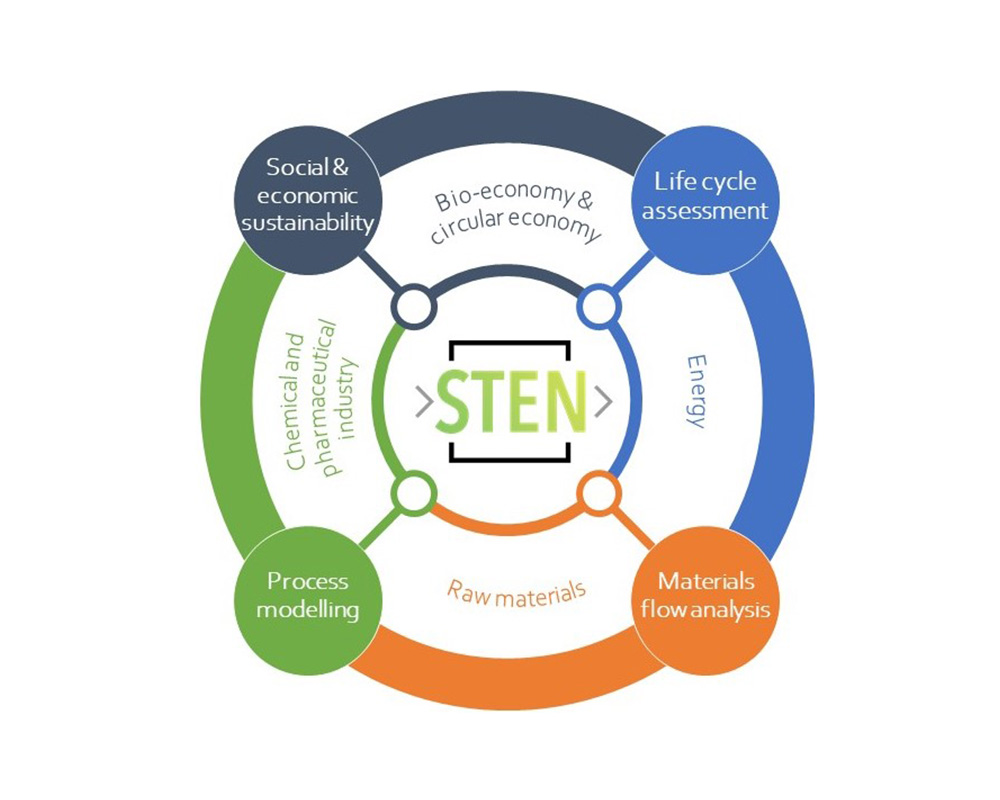

Ghent University has a strong record in raw materials research and education. The Sustainable Systems Engineering (STEN) research group focuses on the study of sustainability aspects, using life cycle thinking and sustainability analysis. Its main role in the RecyLIB project will lead to the socio-environmental sustainability assessment of the (re)manufacturing and recycling technologies.Your contact person for requests about the project – name will be published on the website

Lígia da Silva Lima

(PhD researcher, Research Group Sustainable Systems Engineering (STEN))

E-Mail: ligia.lima@ugent.be

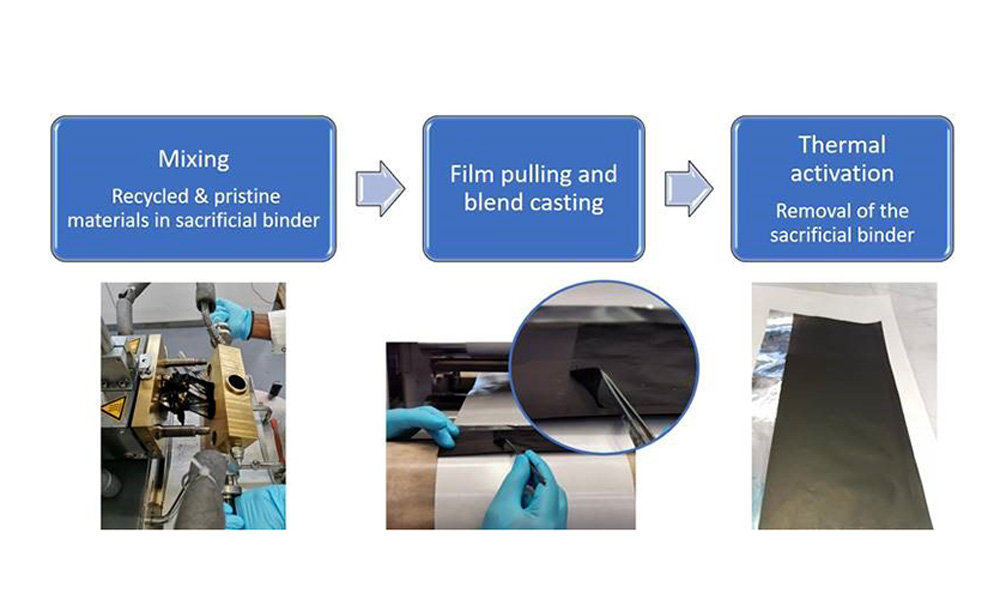

Hutchinson designs and manufactures smart solutions for sustainable mobility on land, in the air and at sea. For this, Hutchinson has a recognized expertise in polymer products with specialties in vibration, acoustic and thermal insulation, sealing systems, fluid transfer and transmission systems. The company has also used its knowledge in polymers chemistry and manufacturing processes to develop a direct method of Li-ion batteries electrodes remanufacturing.

Ksenia Astafyeva

(Head of Multi-Materials Interfaces at the Hutchinson Research and Innovations Centre)

E-Mail: ksenia.astafyeva@hutchinson.com

ImpulsTec is a high-tech company based in Radebeul, Germany, which builds and sells high-voltage pulse systems as well as components for high-voltage pulse technology. The main focus is currently on the development and realization of industrial shock wave fragmentation plants. ImpulsTec can rely on the know-how of a number of national and international partners in the fields of high-voltage technology and mechanical processing technology and is well integrated in a network of corresponding companies and research institutes in this field. Within the RecyLIB project ImpulsTec uses its shock wave fragmentation technology to develop a selective disintegration of novel electrode foils or battery cells.

Stefan Eisert

(CEO ImpulsTec GmbH)

E-Mail: stefan.eisert@impulstec.com

Associated partners

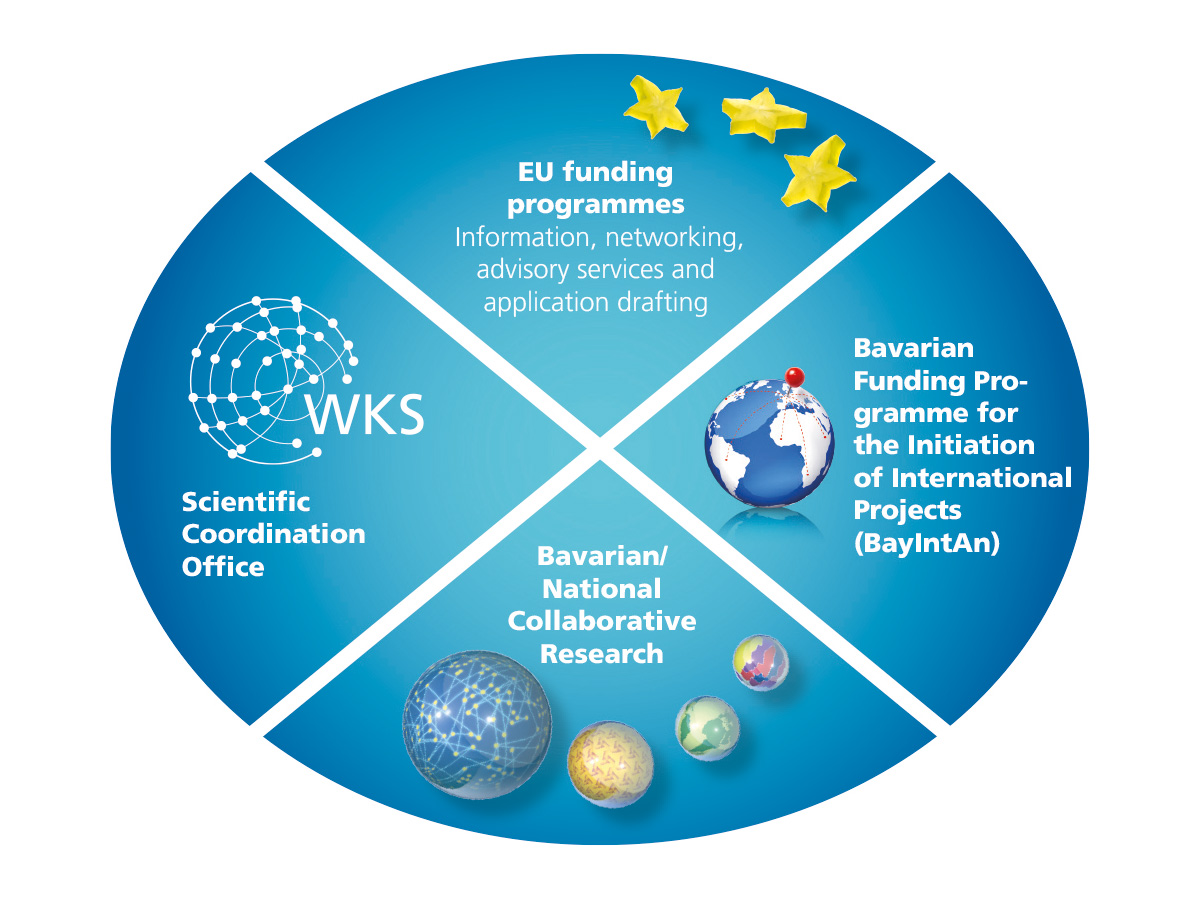

BayFOR as a non-profit entity supports consortia in applying for EU-funds (mainly Horizon Europe). It organizes info- & brokerage events on “Batteries” as one of its key strategic areas.

In addition, BayFOR is partner in the Enterprise Europe Network and the Bavarian Research and Innovation agency and member in Batteries European Partnership Association for advising and dissemination activities.

Dr. Daniel Kießling

(Scientific Officer Bavarian Research Alliance GmbH)

E-Mail: kiessling@bayfor.org

Wherever materials need to be neatly separated for their recovery, subsequent processing and disposal, CEPA supplies concepts that make perfect economic sense and are

tailored exactly to your requirements.

From the standard model to custom‐built systems, customers worldwide benefit from CEPA’s many years of expertise and innovative technology as a leader in the field of

planning, designing and producing centrifuges. Discover all‐round perfection in a variety of designs and versions.

For RecyLIB CEPA supports the partners by providing know how on centrifuge application in lithium‐ion‐battery recycling.

Felix Seiser

(Project Manager Research, CEPA GmbH)

E-Mail: f.seiser@cepa.de